MAX Energy

Assets

MAX ENERGY ASSETS

Max Energy bridges the gap between upstream and downstream with our unique asset footprint and capabilities. Our high-capacity network of pipelines, interconnects, storage and terminal facilities offer a seamless, one-stop solution for premium midstream operations.

ENERGY INNOVATION

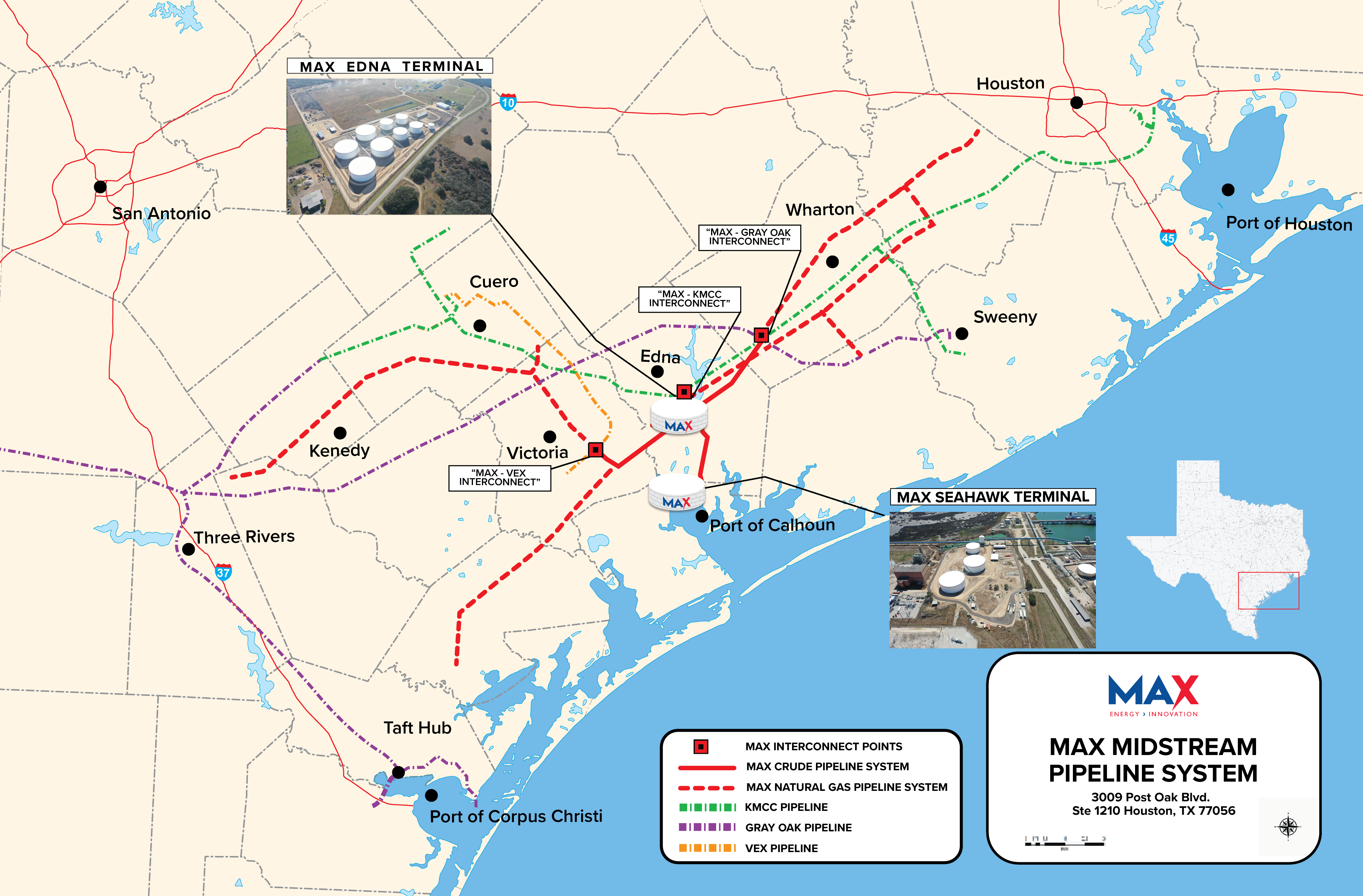

Max Energy offers convenient pipeline access from the Permian and Eagle Ford Basin directly to its Seahawk Terminal in the Port of Calhoun, Texas.

By March 2022, we completed an aggressive pipeline (Phase 1) which includes:

- Interconnection with the Kinder Morgan Crude and Condensate pipeline (KMCC) to our new Edna Terminal, with the Seahawk Pipeline to our Seahawk Terminal in Point Comfort

- Connection of the Seahawk Pipeline to connect our Edna Terminal and Seahawk Terminal in Point Comfort

- Expansion of existing storage at the Seahawk Terminal, new storage and truck LACT receipts at Edna Terminal, and more loading capabilities at the Port with a new Multi-purpose Dock (MPD) that is dedicated to Max Midstream and allows for inbound/outbound segregated barge shipments

- Max has acquired a strategically located natural gas line consisting of 328 miles of 8-16-inch pipelines along the Gulf Coast. The acquisition provides numerous intersection points with major crude pipelines that run from Eagle Ford and Permian Basins towards Corpus Christi, Houston, and Edna for Port of Calhoun exports. The Gray Oak Pipeline and Victoria Express (VEX) Pipeline intersect (Phase 2A) should be brought into service through Q3 2024.

These enhancements will be the foundation for potential new projects such as, additional storage, marine combustion units and new berth construction for crude exports, refined products exports, rail inbound / outbound movements, thus, making the Port of Calhoun a multi-modal port.

SEAHAWK TERMINAL

FEATURES

- • 612,000 barrels of crude / condensate storage capacity in operation and consisting of:

- • 2 x 250,000 bbl API 650 IFR storage tanks

- • 1 x 112,000 bbl API 650 IFR storage tank

- • Panamax-sized vessels

- • Loading arms at the liquids pier for both domestic and international vessels with a flow rate of 15,000 barrels per hour (“BPH”)

- • Four loading berths to service barges and Articulated Tug Barges (ATB’s) at the Max dedicated Multi-purpose Dock (MPD) capable of loading two barges simultaneously at 10,000 BPH

- • Two Marine Vapor Combustion Units (VCU) upgraded to load at 15,000 BPH each

- • Local office at Seahawk Terminal with 24/7 Supervisory Control and Data Acquisition (SCADA) operations oversight for the pipeline, export docks and storage facilities

- • Additional expansion plans within the Seahawk Terminal of ~1.0m bbl of crude storage

- • Additional marine combustion units and new berth construction for Max Midstream Customers

BENEFITS OF SEAHAWK TERMINAL

- • Strategically located between Corpus Christi and Houston / Galveston ports with direct access to the US Gulf, Intercoastal Waterway, and the Matagorda Shipping Channel

- • Advantaged proximity to Texas Gulf Coast Reverse Lightering zones to load larger vessels

- • Lack of congestion in the Port of Calhoun, allows for shorter wait times and minimizes congestion-related demurrage charges.

PORT EXPANSION

The Matagorda Ship Channel Improvement Project (MSCIP) is sponsored by the Calhoun County Port Authority. Congress authorized the Army Corps of Engineers to construct the MSCIP in Calhoun and Matagorda Counties. This project will improve the navigational efficiency and operational safety of the deep-draft navigation system of the port. The result of the project will allow the users of the Port of Calhoun to accommodate up to Aframax class ships. The deepening and widening dredge is currently anticipated to start in late 2025 (More updates to come through 2024).

PORT / BAY PILOT CONTACT DETAILS

Edna Terminal

FEATURES

- • 1.5 million barrels of crude / condensate storage capacity in operation and consisting of:

- • 4 x 125,000 bbl API 650 IFR storage tanks

- • 4 x 250,000 bbl API 650 IFR storage tanks

- • 24” KMCC Interconnect

- • 6 Truck LACT bays

- • Blending facilities to optimize crude slates for export value

- • Local office at Edna Terminal with 24/7 SCADA operations oversight for the pipeline and storage facilities

BENEFITS OF EDNA TERMINAL

- • Ability to flow from Edna Terminal tanks directly to a barge at Point Comfort without requirement for breakout storage

- • Sparging system on all tanks for ease of blending and Trck lact system having dedicated lines to certain tanks at terminal

- • 3rd party inspection facility located at the Edna Office build which is adjacent to the terminal (Camin Cargo)

Our API 650 above ground tanks have floating roofs and bottom draw’s, allowing us to handle varying grades of crude oil and efficiently manage tank bottom’s. In addition, it makes it possible to segregate specialty grades of crude oil for our customers and protect the quality specifications of their crude oil.

PIPELINES

MAx Pipeline System

The Max Pipeline System consists of ~350 miles of 8-16-inch pipelines along the Texas Gulf Coast. The pipeline provides numerous intersection points with major crude pipelines that run from Permian and Eagle Ford Basins towards Corpus Christi, Houston, and Edna for Port of Calhoun exports. The current crude service covers ~65 miles with interconnects to the Gray Oak Pipeline and Victoria Express (VEX) Pipeline (Phase 2A – in service through Q3 2024) allowing for crude/condensate to domestic and international markets.

eNVIRONMENT & SAFETY

All facilities will meet or exceed all environmental, safety guidelines, American Petroleum Institute (API) recommendations, applicable regulatory standards, and accepted industry practices.

QUALITY ASSURANCE

To ensure quality control and offer segregated crude oil exports at its terminal in the Port, Max Midstream will be partnering with best-in-class organizations to assist in the design of its control rooms, conduct testing and certification of the crude oil, and utilize proprietary methods for crude blends that domestic and international refiners require for their processes.